2. Are energy returns from oil sands extraction lower than conventional oil?

Previous works have calculated the energy returns from oil sands production using a variety of methods (Peter 2010; Herweyer and Gupta 2008; Rapier 2008; Peter 2012; DOE 2006). These studies estimate EROI from the oil sands at values ranging from 2.5 GJ/GJ to 7 GJ/GJ. Most of these estimates were generated quite simply, relying on a limited amount of data. Because of the different system boundaries used in each study, as well as other methodological differences, determining the exact reasons for variation in these estimates is challenging.

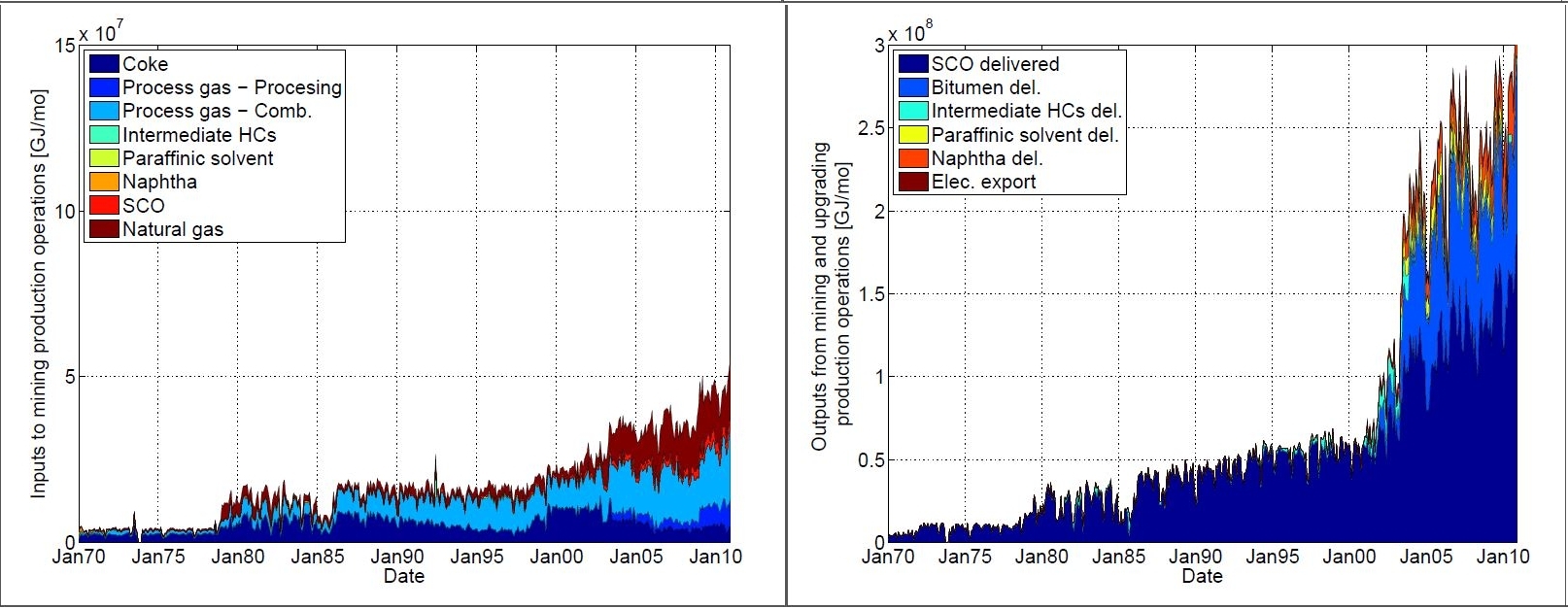

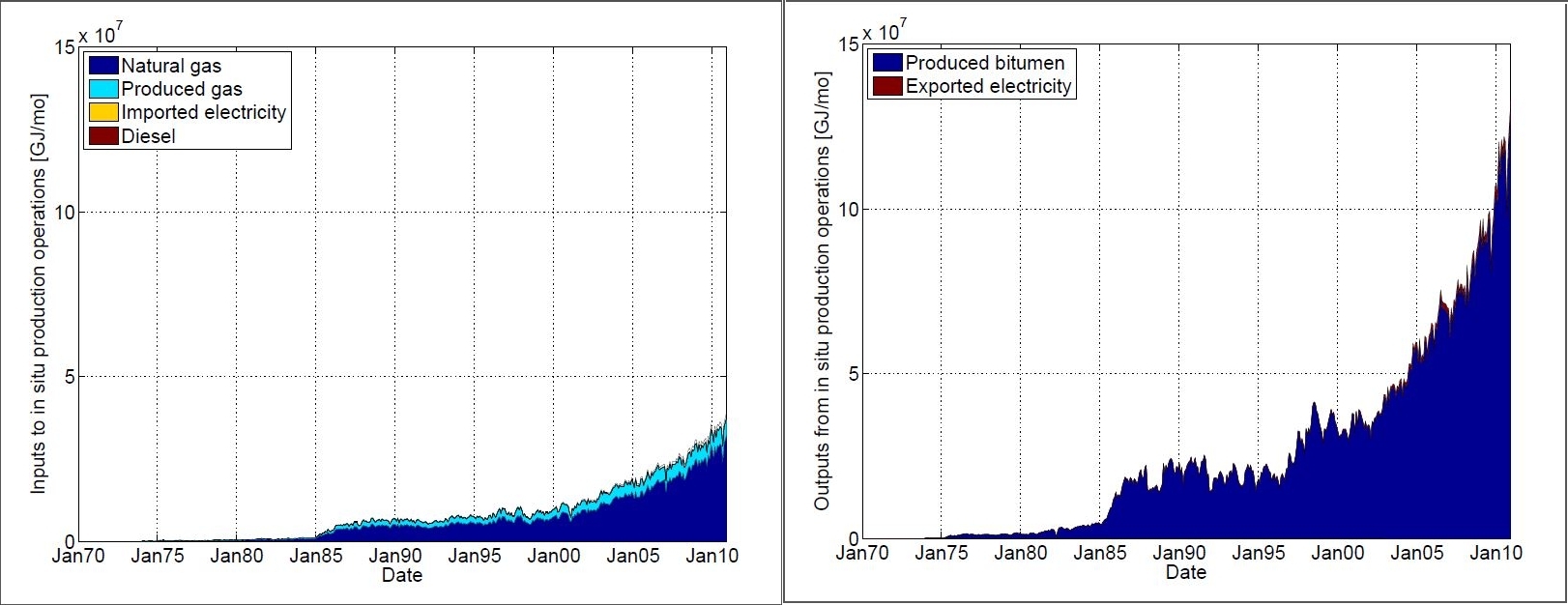

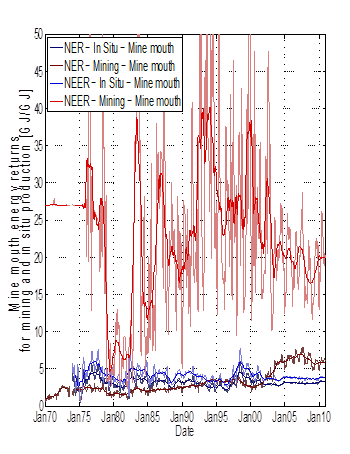

Our recent work (Brandt et al. 2013) utilized detailed energy production and consumption data reported by oil sands producers from 1970 to 2010 to examine trends in historical energy returns from oil sands extraction. The system diagram and flows considered are shown in Figures 1 and 2. Data are available on a monthly basis for most flows, with limited interpolation required in mining datasets, and some back-extrapolation required for in-situ energy intensities (see Brandt et al. (2013) for methodological details). The resulting energy inputs and outputs from mining and in situ production are shown in Figures 3 and 4. Mine mouth (e.g., extraction only, excluding refining) net energy returns (NER) for the entire industry were found to be 5.23 GJ/GJ in 2010. In situ NERs were approximately 3.5 to 4 GJ/GJ in 2010 while mining NERs were approximately 5.5 to 6 GJ/GJ.

Conventional oil EROI metrics commonly show energy returns of order 10-20 GJ/GJ (Gagnon 2009 et al.; Guilford et al., 2011; Dale et al. 2011). Therefore, oil sands projects exhibit demonstrably lower energy returns than conventional oil operations.

Net energy returns from mining and in situ operations (again, measured at a mine-mouth system boundary) have increased steadily over time, growing from 1.0 GJ/GJ in 1970 (entirely from the Suncor mining operation) to 2.95 GJ/GJ in 1990 and then to 5.23 GJ/GJ in 2010. As shown in Figure 5, significant improvements in mining energy returns have been realized.

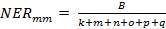

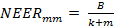

The net energy returns reported above are just one metric to assess the energy returns from oil sands operations. Using the key provided in Figure 1 for mining operations (top), a mine-mouth NER compares the net output from the mining and upgrading operation to the total energy inputs into the mining and upgrading stage. Symbolically, this can be written as:

Measured in this way, the NEER from mining operations was approximately 20 GJ/GJ in 2010, significantly higher than the corresponding NER (see Figure 5).

5. Will low energy returns limit the output of net energy from the oil sands?

These data suggest that oil sands processes exist that have reasonably high energetic returns relative to external energy provided by other energy sectors. That is, relative to the amount of energy that they consumed from the rest of society (e.g., natural gas, imported diesel, and electricity), these processes produce a significant amount of net energy output. This is partly a result of historical development and geographic considerations: the oil sands mining operations developed in a remote and poorly-integrated part of Alberta, and therefore were designed to be largely energy self-sufficient. Importantly, these conclusions are not just limited to mining operations. In situ operations such as the Nexen Long Lake project produce steam using upgrader by-products (asphaltene residues).

Our results suggest that it is not realistic to expect oil sands extraction to be limited by their calls on natural gas and other resources. If natural gas becomes expensive, processes can be adopted to use byproducts of the processing of bitumen to fuel extraction (e.g., integrated operations).?However, these integrated processes have implications for the amount of oil sands resource available (e.g., not all barrels able to be produced will be available as ?net? barrels of output) and can have important climate implications (e.g., using coke for fueling bitumen separation or steam production is more GHG intensive than using natural gas).

The Oil Drum

felix hernandez julia child Ron Palillo Chad Johnson Twitter

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.